Metal Roof Waterproofing Coating

Metal roof waterproof coating is made of pure acrylic emulsion as main material, mixed with other good quality pigment. The non-woven polyester cloth could be applied as base reinforcement material.

Product Description:

Metal roof waterproof coating is made of pure acrylic emulsion as main material, mixed with other good quality pigment. The non-woven polyester cloth could be applied as base reinforcement material.

Product Details Pic:

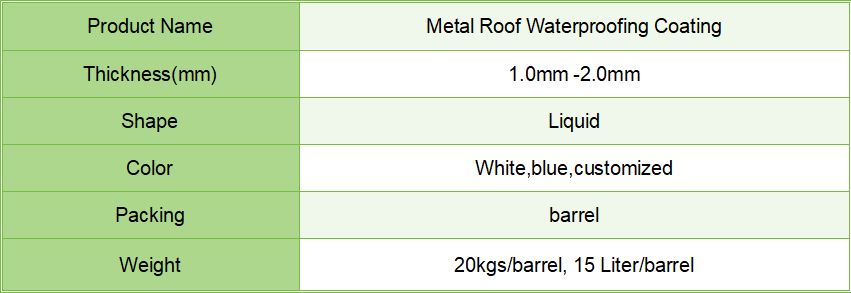

Product Spec:

Product Feature:

1.Prominent waterproof performance

2.Excellent resistance to aging ,corrosion , rust and high temperature

3.Good low temperature flexibility and elastic performance

4. No-toxic, harmless and friendly environmental

5.It can be used widely,easy to apply

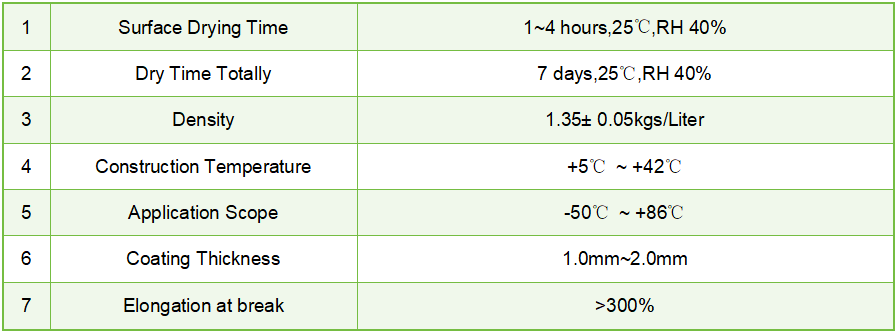

Technical Data:

Product Application:

It is widely used for all kinds of metal roofing, such as IBR sheet, aluminum sheet, glass roofs, daylighting panel roofing and concrete roof with the following benefits:

* excellent weatherproof to solve water leakage problem

* good corrosion and rust resistance property

* UV ray resistance to extend the relevant building life span.

How to use it:

Construction general procedure is as follows:

1. Clean metal roofing to make sure the surface is clean without metal rust. Otherwise, use the wire brush and sand cloth to clean the rust.

2. Make sure two panel sheet joint, wall corner and ventilation duct ready for brushing one layer of metal coating as primer and laying reinforced polyester cloth.

3. Use the brush or roller to paint one layer of metal waterproof coating for whole area of panels as primer. The usual covering area standard is 40 square meter for 20 liters of metal coating.

4. The second layer of metal waterproof coating is brushed in horizontal direction for whole area after the primer is dry for 12 hours.

5. The third layer of metal waterproof coating is brushed again in vertical direction for whole covering areas after the second layer is dry.

The above method is one reinforcement cloth with three layers of painting.

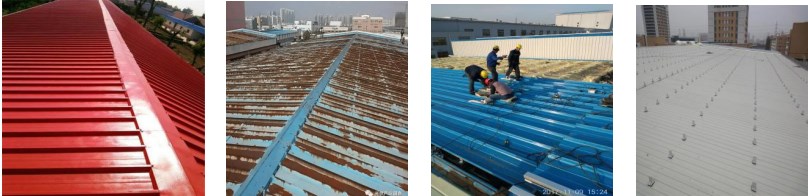

Construction Illustration: