Single Component Water Based Coating PU Waterproof Coating

Single component waterproof coating also called PU 951 is a kind of environmental friendly water based waterproof coating, made of EVA and acrylic emulsion. After being coated, it forms high elastic

Product Description:

Single component waterproof coating also called PU 951 is a kind of environmental friendly water based waterproof coating, made of EVA and acrylic emulsion. After being coated, it forms high elastic rubber film on the base surface, which is flexible, durable and non-toxic, suitable for roofing, toilet, kitchen, swimming pool, window sill and basement.

Product Details Pic:

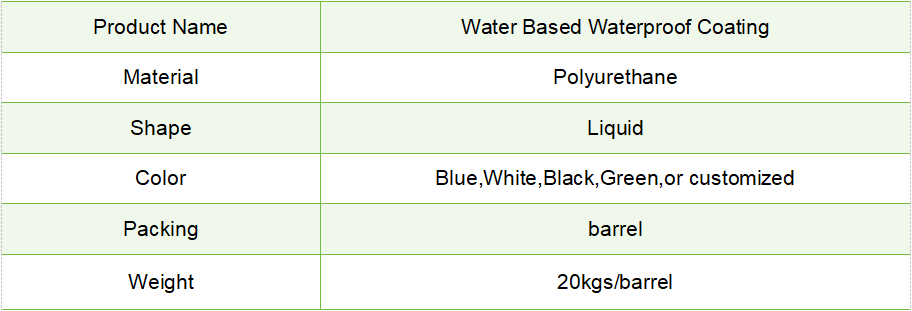

Product Spec:

Product Feature:

1) Adjustable color, non-toxic and tasteless, convenient construction

2) Coated film after high elongation, high tensile strength, good waterproof effect

3)Liquid normal temperature construction without joints

4) Good water resistance, good weather resistance

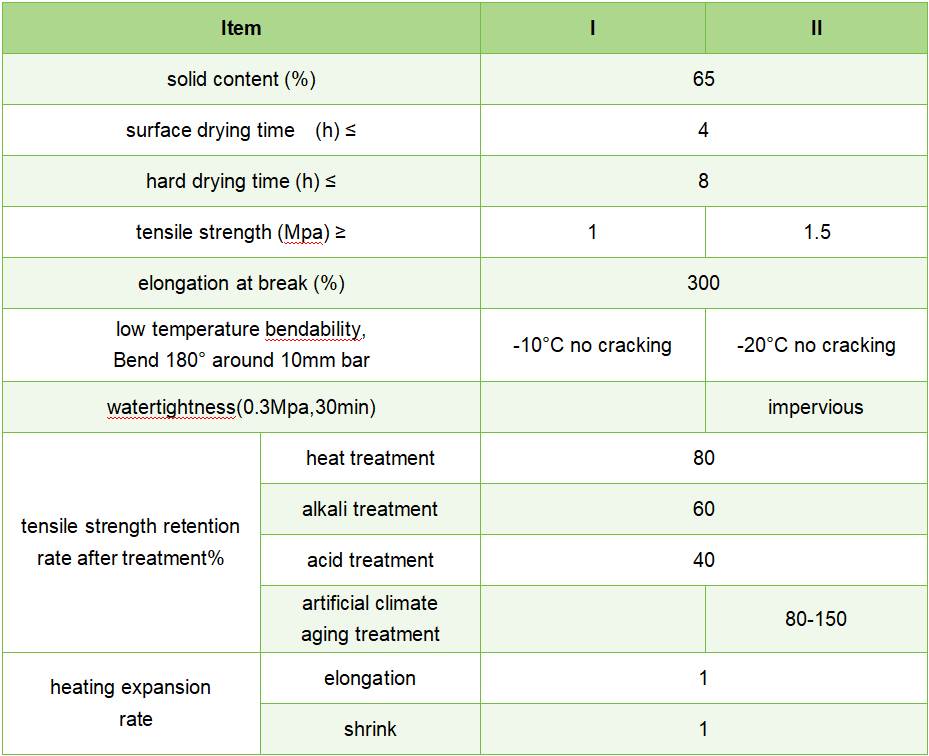

Technical Data:

Product Application:

1.Waterproof project for roofing,basement,pool,underground building, kitchen, bathroom and toilet etc.

2.Leakage prevention of sewage tank

3.Waterproof and anticorrosive of underground pipelines, waterproof of high-speed railway and bridge structures

4.Bathroom, toilet, basement, kitchen

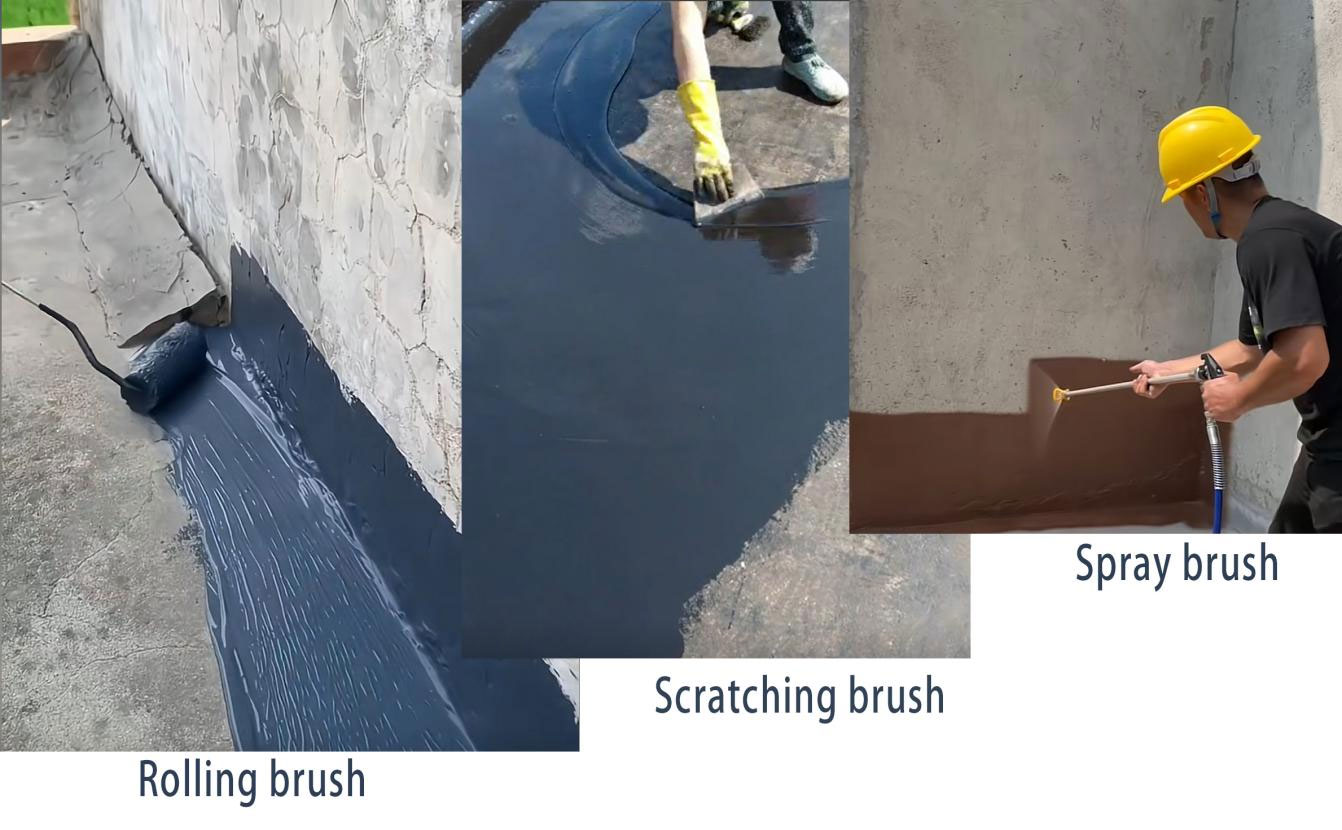

Construction Guidance &Illustration:

Construction general procedure is as following:

1.Base treatment: the base must be smooth and firm, clean, no clear water, Yin and Yang Angle should be made into a circular arc.The old roof should be the original broken, drum waterproof house and dust removal, concave damage repair level, leak prevention must be first plugging treatment, the base level, no clear water.Special parts such as waterfall mouth and lattice joint should be flexible sealing treatment first.Brushing procedure is generally Yin and Yang Angle first, then vertical plane, and finally large area construction.

2.Bottom coating construction: water and paint according to the weight ratio of 1:3, mixing evenly after use.The use of the bottom coating can improve the permeability of the coating to the base, enhance the cohesion.

3.Coating: construction using rolling, scraping, brush method can be used, should use thin layer coating method, each brushing can not be too thick, generally divided into 3-4 brushing, total thickness of 1.5-2.0mm.To be the first coating dry film can be coated after a coating.The weak link should be covered with fetal body reinforcement material.

4.After each coating surface dry, should be construction quality inspection, such as leakage and drum should be given repair.